Optimized Fleet Solutions

Aviation Classics shows diverse technical and operational expertise in U.S. and Foreign Military Aviation. This expertise gives us the capability and flexibility to support various programs, government and civilian.

We appreciate your consideration of Aviation Classics Ltd. and our innovative solutions.

ACL as a small, accomplished 8A business, is experienced in supporting national company’s government contracts.

C-130, RTIC Program (Real-Time Information in the Cockpit)

As a second tier Sub-Contractor under NGIS RTIC Modification Contract H94003‐04‐D‐0005.0030, ACL provided FAA licensed personnel for the initial Site Survey of C-130H 2.0-3.0 Block aircraft, and follow-on initial and ongoing installation design and integration phase modifications.

ACL provided the necessary FAA licensed Airframe & Powerplant technicians and supervisor for the initial 12 TVI installs (Test Vehicle Installations), and for follow-on LRIP installs (Low Rate Initial Production) at ANG/AFRC installations in Charleston, West Virginia, Youngstown, Ohio, Minneapolis, Minnesota, Schenectady, New York and Louisville, Kentucky.

ACL also participated in the Flight Test Program on the first two RTIC TVI’s working with Northrop Grumman Engineers at DMAFB, and performed Quality Control Inspections and necessary Field Modifications with Northrop Grumman staff.

ACL completed 24 of the C-130 RTIC modifications before its request to be contractually released from Borsight LLC.

Pictured:

Typical C-130H-2.5, RTIC Mod Aircraft

- FAA Form 8130 and 337 Documentation & Engineering Approvals

- C-130 Structural Substantiation Reports

- Initial Field Modifications

- Electrical Harness Installation & Harness Troubleshooting

- Rack Modification and Installation

- Manufacture, Corrosion Control/painting and Installation of Doubler-Kits for RTIC Lower UHF Antenna

- Installation of RTIC lower UHF Antenna

- Installation of SADL upper Satcom Antenna

- Installation of the TacView Control Yoke & Cockpit Side Mounts

- Installation of Control Box at Navigator Station

- Installation of RCCB in Circuit Breaker Control area

- Installation of EMU’s (2) under Flight Engineer Seat

- Developed the TacView Sidemount Bracket

- Compliance with Air Force Tool Control and Accountability procedures

C-130, RTIC Program (Real-Time Information in the Cockpit)

As a second tier Sub-Contractor under NGIS RTIC Modification Contract H94003‐04‐D‐0005.0030, ACL provided FAA licensed personnel for the initial Site Survey of C-130H 2.0-3.0 Block aircraft, and follow-on initial and ongoing installation design and integration phase modifications.

ACL provided the necessary FAA licensed Airframe & Powerplant technicians and supervisor for the initial 12 TVI installs (Test Vehicle Installations), and for follow-on LRIP installs (Low Rate Initial Production) at ANG/AFRC installations in Charleston, West Virginia, Youngstown, Ohio, Minneapolis, Minnesota, Schenectady, New York and Louisville, Kentucky.

ACL also participated in the Flight Test Program on the first two RTIC TVI’s working with Northrop Grumman Engineers at DMAFB, and performed Quality Control Inspections and necessary Field Modifications with Northrop Grumman staff.

ACL completed 24 of the C-130 RTIC modifications before its request to be contractually released from Borsight LLC.

Pictured:

Typical C-130H-2.5, RTIC Mod Aircraft

- FAA Form 8130 and 337 Documentation & Engineering Approvals

- C-130 Structural Substantiation Reports

- Initial Field Modifications

- Electrical Harness Installation & Harness Troubleshooting

- Rack Modification and Installation

- Manufacture, Corrosion Control/painting and Installation of Doubler-Kits for RTIC Lower UHF Antenna

- Installation of RTIC lower UHF Antenna

- Installation of SADL upper Satcom Antenna

- Installation of the TacView Control Yoke & Cockpit Side Mounts

- Installation of Control Box at Navigator Station

- Installation of RCCB in Circuit Breaker Control area

- Installation of EMU’s (2) under Flight Engineer Seat

- Developed the TacView Sidemount Bracket

- Compliance with Air Force Tool Control and Accountability procedures

RC-26B, DF-12 Mount

ACL provided recent services to the USAF’s RC-26 Program: as a Sub-Contractor. ACL designed, fabricated, and kitted the DF-12 Antenna Mount Assembly, manufacturing hardpoints, panels, aerodynamic fairing, and coaxial cables. Working with a local engineering, structural, and aerodynamic analysis firm, ACL created necessary FAA documentation, Form 337, and Form 8110-3, and completed Data Packages. ACL’s FAA-licensed mechanics & supervisory staff traveled and installed the DF-12 Assembly on two Hurlburt-based C-26B’s. An additional 4 Kits, were assembled and shipped to LSI, San Antonio, Texas to be installed on aircraft overseas.

Pictured:

First Row: RC-26 DF-12 Antenna Mount Design Stage | Second Row: DF-12 Prototype Fabrication Stage | Third & Fourth Row: RC026 with DF-12 Antenna Array and Mount – Final Installation

RC-26B, DF-12 Mount

ACL provided recent services to the USAF’s RC-26 Program: as a Sub-Contractor. ACL designed, fabricated, and kitted the DF-12 Antenna Mount Assembly, manufacturing hardpoints, panels, aerodynamic fairing, and coaxial cables. Working with a local engineering, structural, and aerodynamic analysis firm, ACL created necessary FAA documentation, Form 337, and Form 8110-3, and completed Data Packages. ACL’s FAA-licensed mechanics & supervisory staff traveled and installed the DF-12 Assembly on two Hurlburt-based C-26B’s. An additional 4 Kits, were assembled and shipped to LSI, San Antonio, Texas to be installed on aircraft overseas.

Pictured:

Images 1 & 2: RC-26 DF-12 Antenna Mount Design Stage | Images 3 & 4: DF-12 Prototype Fabrication Stage | Images 5 , 6 & 7: RC026 with DF-12 Antenna Array and Mount – Final Installation

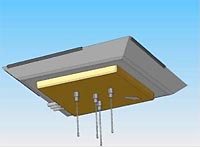

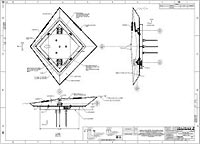

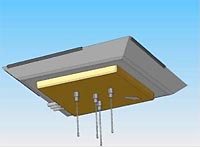

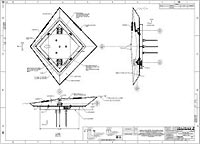

RC-26B, UAM (Universal Antenna Mount)

As a Sub-Contractor, and working closely with LSI and the Air Force, Aviation Classics Ltd. designed, fabricated, and kitted the UNIVERSAL Antenna Mount, manufacturing hardpoints, panels, aerodynamic fairing, and coaxial cables. Working with a local engineering, structural, and aerodynamic analysis firm, ACL created necessary FAA documentation, Form 337, and Form 8110-3’s. ACL’s FAA-licensed mechanics and supervisory staff traveled and installed the UAM on two Hurlburt-based C-26B’s. An additional 4 Kits, were assembled and shipped to LSI, San Antonio, Texas to be installed on aircraft overseas.

Pictured:

First Row, Left: UAM: Design Stage | First Row, Right: UAM Kitted and ready for overseas shipment | Second Row: UAM Prototype: Initial Fit

RC-26B, UAM (Universal Antenna Mount)

As a Sub-Contractor, and working closely with LSI and the Air Force, Aviation Classics Ltd. designed, fabricated, and kitted the UNIVERSAL Antenna Mount, manufacturing hardpoints, panels, aerodynamic fairing, and coaxial cables. Working with a local engineering, structural, and aerodynamic analysis firm, ACL created necessary FAA documentation, Form 337, and Form 8110-3’s. ACL’s FAA-licensed mechanics and supervisory staff traveled and installed the UAM on two Hurlburt-based C-26B’s. An additional 4 Kits, were assembled and shipped to LSI, San Antonio, Texas to be installed on aircraft overseas.

Pictured:

First Row, Left: UAM: Design Stage | First Row, Right: UAM Kitted and ready for overseas shipment | Second Row: UAM Prototype: Initial Fit

Pictured:

UAM: Design Stage | UAM Kitted and ready for overseas shipment | UAM Prototype: Initial Fit

RC-26B, P-System Antenna & Modification

As a Subcontractor working closely with LSI, the AFRL, and the Air Force, designed and fabricated necessary doublers, and modified the vertical stabilizer to accept Lasar antennas, routing necessary coaxial cables to P-Sys components. ACL created necessary FAA documentation, Form 337, and Form 8110-3 as acceptable data. ACL’s FAA-licensed mechanics and supervisory staff traveled and installed the P-Sys Antenna Modification on one Hurlburt-based C-26B.

Pictured:

First Row, Left: P-Sys/Lasar Modification | First Row, Right: RC-26B Vertical Stabilizer Modification | Third Row: P-Sys/Lasar Antenna Installation: Completed, prior to test flight

P-SYS Range Enhancement

In addition, ACL personnel studied and troubleshot the operational RC-26B P-System, and Ground Station at Hurlburt. ACL then designed a diversity receiver, and provided necessary modifications and component changes to the P-System equipped RC-26B configuration: the result increased P-Sys transmit and receive ranges from intermittent 5/10 miles, to 85 miles--steady state.

ACL also installed a ground based transmit capability for the 745th Squadron, by modifying the P-Sys ground receive tower, adding a transmit antenna and a second RF Amp.

Pictured:

First Row, Left: P-Sys/Lasar Modification | First Row, Right: RC-26B Vertical Stabilizer Modification | Third Row: P-Sys/Lasar Antenna Installation: Completed, prior to test flight

Pictured:

P-Sys/Lasar Modification | RC-26B Vertical Stabilizer Modification | P-Sys/Lasar Antenna Installation: Completed, prior to test flight

P-SYS Range Enhancement

In addition, ACL personnel studied and troubleshot the operational RC-26B P-System, and Ground Station at Hurlburt. ACL then designed a diversity receiver, and provided necessary modifications and component changes to the P-System equipped RC-26B configuration: the result increased P-Sys transmit and receive ranges from intermittent 5/10 miles, to 85 miles--steady state.

ACL also installed a ground based transmit capability for the 745th Squadron, by modifying the P-Sys ground receive tower, adding a transmit antenna and a second RF Amp.

RC-26B, P-System Antenna & Modification

As a Subcontractor working closely with LSI, the AFRL, and the Air Force, designed and fabricated necessary doublers, and modified the vertical stabilizer to accept Lasar antennas, routing necessary coaxial cables to P-Sys components. ACL created necessary FAA documentation, Form 337, and Form 8110-3 as acceptable data. ACL’s FAA-licensed mechanics and supervisory staff traveled and installed the P-Sys Antenna Modification on one Hurlburt-based C-26B.